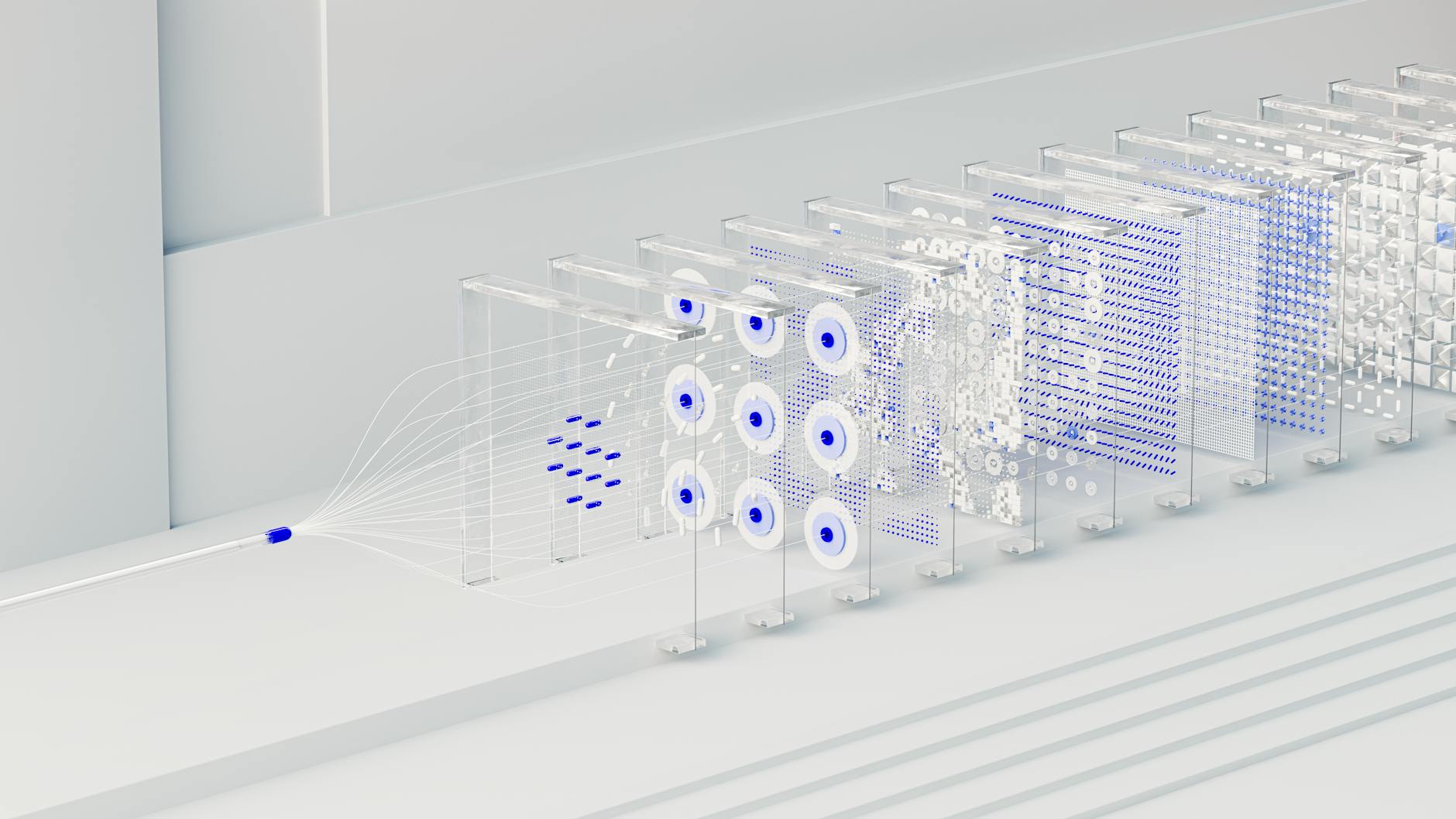

The data center market in the Americas is no longer just growing. The AI boom is surging at a pace that is fundamentally altering the global digital landscape. According to recent industry analysis from Business Facilities, the Americas have solidified their lead as global data center capacity explodes. This lead is largely driven by the unrelenting demand for Artificial Intelligence (AI) and high-performance computing (HPC).

As of 2025, the U.S. remains the epicenter of this expansion. Northern Virginia, the world’s largest data center market, saw under-construction capacity jump by 80% in the first half of 2025 alone (CBRE). However, this rapid growth brings two critical challenges that threaten to stall the AI revolution. Unprecedented energy demand and the silent degradation of cooling infrastructure.

At Coat Zone, we believe that the key to sustaining the AI boom isn’t just about building more. It’s about protecting and optimizing what we already have.

The Energy Paradox: AI’s Massive Cooling Appetite

Data centers are among the most energy-intensive facilities on Earth. In 2024, data centers consumed approximately 183 terawatt-hours (TWh) in the U.S. alone—roughly 4% of the country’s total electricity (Pew Research). By 2030, this demand is projected to grow by 133% to 426 TWh.

The “energy hog” in the room is cooling.

- The Cooling Tax: Cooling systems are the second-largest energy consumer in a data center. They account for 30% to 50% of total energy use in less-efficient enterprise facilities (IEA/Coat Zone).

- The AI Multiplier: AI-focused servers generate significantly more heat than traditional servers, requiring 2 to 4 times the power and, consequently, a massive increase in cooling capacity to prevent catastrophic hardware failure.

When cooling efficiency drops even by a small percentage, the Power Usage Effectiveness (PUE) of a data center skyrockets. This drop leads to millions of dollars in wasted operational expenditure (OpEx).

The Corrosion Threat: A Silent Saboteur of Uptime

While power grids struggle to keep up with demand, environmental factors are attacking the very machines designed to provide relief. Corrosion is a primary cause of HVAC failure, responsible for nearly 40% of equipment failures in industrial settings (CED Engineering).

In data center hubs—ranging from the humid corridors of the East Coast to industrial zones in the Midwest—cooling coils are under constant attack from:

- Salt Air & Humidity: Accelerating the oxidation of aluminum and copper.

- Pollutants & “Electrolytes”: Gaseous contaminants that cause pitting and “formicary” corrosion, which can lead to refrigerant leaks and total system failure in less than a year.

- Thermal Stress: Constant 24/7 operation at high loads accelerates the mechanical degradation of the bond between HVAC fins and tubes, reducing heat transfer by 15–20% over just five years (IRE Journals).

Re-Engineering Resilience for the AI Boom

To meet the goals of the “Americas-first” data center expansion, facilities must shift from a “replace-on-failure” mindset to a “protect-and-optimize” strategy. Coat Zone’s dual-coating approach provides a high-impact, low-cost shield for the infrastructure powering the AI boom:

- CoilSafe® & CoilSafe Plus® (Internal Protection): These ultra-thin (8–10 micron) inorganic coatings bond covalently to HVAC coils. Unlike traditional thick coatings, they do not impede heat exchange. By preventing corrosion and “fouling” (the buildup of dirt and microbes), CoilSafe can improve HVAC efficiency by up to 10% and maintain near-factory performance for the life of the unit.

- ThermalBlock™ (External Defense): Applied to exterior cabinets and rooftop ductwork, ThermalBlock acts as a radiant barrier that blocks up to 93% of solar heat. By keeping the unit’s cabinet temperature within 10°F of ambient air, it drastically reduces the “thermal load,” allowing the system to run less frequently and consuming significantly less kWh during peak demand.

Sustaining the AI Boom with ROI

As Business Facilities highlights, the Americas are leading the charge in capacity, but that leadership requires a foundation of efficiency. Integrating Coat Zone’s coatings can:

- Reduce cooling energy consumption by 15–30%.

- Extend the useful life of assets by 50% or more, deferring massive capital expenditures.

- Deliver a rapid ROI, typically within 12 to 36 months.

The future of AI is being built today. By protecting the cooling infrastructure that keeps these digital brains alive, Coat Zone is helping ensure that the surge in capacity is matched by a surge in resilience.

Sources:

- Business Facilities: Americas Lead As Global Data Center Capacity Surges (2025).

- CBRE: North America Data Center Trends H1 2025.

- Pew Research: Energy Use at U.S. Data Centers Amid the AI Boom (2025).

- International Energy Agency (IEA): Energy Demand from AI Report (2024/2025).

- IRE Journals: Evaluating Long-Term Effects of Erosion-Corrosion on HVAC (2023/2025).