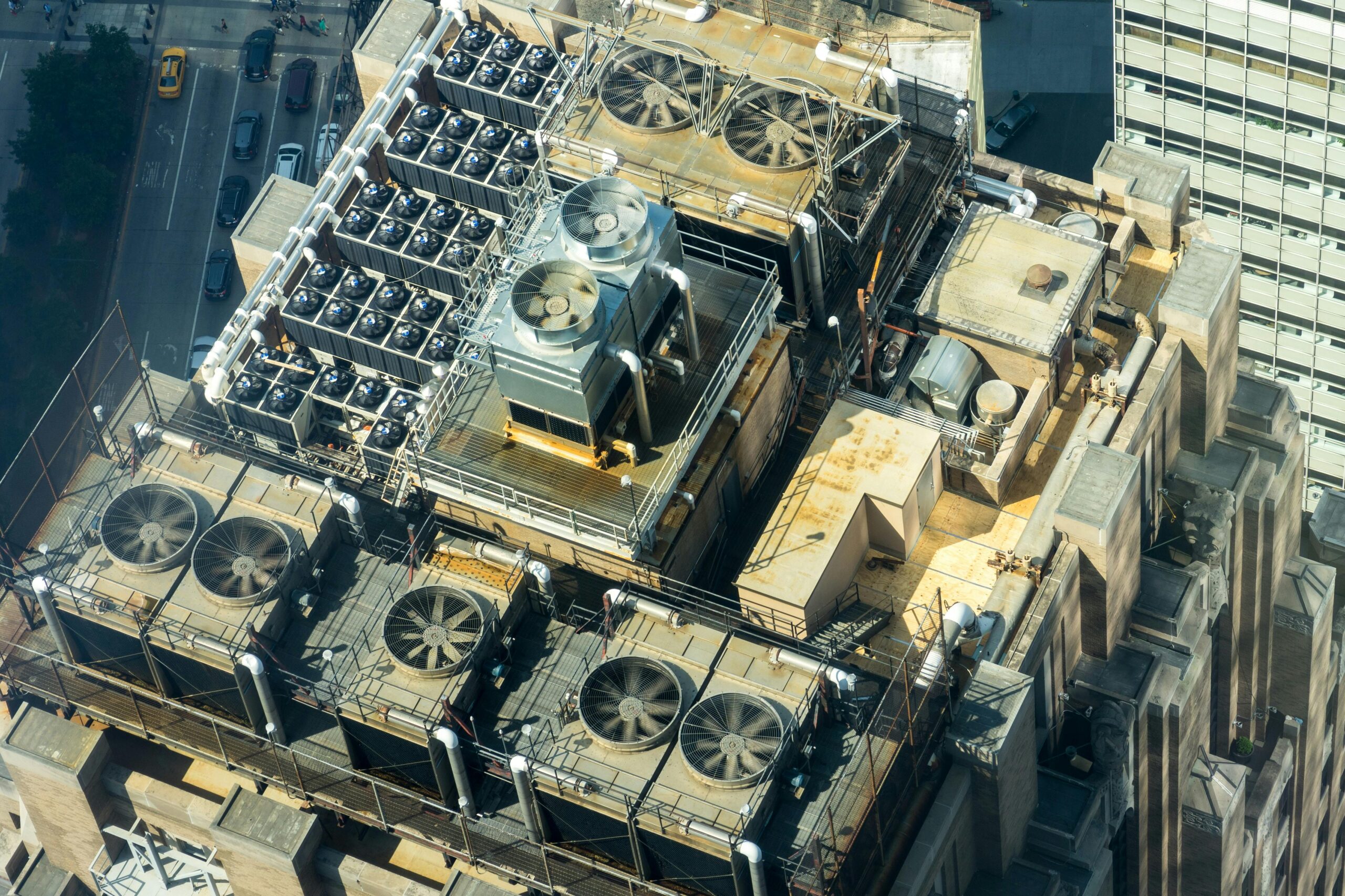

For leaders in the infrastructure sector, the integrity and performance of critical systems are paramount. Among the silent threats that can undermine efficiency, compromise indoor air quality, and even lead to costly downtime is the pervasive issue of mold in HVAC systems. While often overlooked until a problem becomes apparent, understanding what causes mold to proliferate and how to prevent it is crucial for maintaining healthy, efficient, and long-lasting HVAC assets within your commercial and industrial environments.

Why Mold Thrives in HVAC

Mold in HVAC systems isn’t just an aesthetic issue; it’s a significant operational and health concern in large-scale facilities. The conditions within commercial HVAC units—particularly on cooling coils and in drain pans—are often ideal for microbial growth. As emphasized by the U.S. Environmental Protection Agency (EPA), mold growth is fundamentally dependent on the presence of moisture [1]. Several factors contribute to this unwelcome phenomenon in commercial settings:

- Persistent Moisture Accumulation: The primary culprit. Mold spores are ubiquitous and will grow if moisture is present [2]. In commercial HVAC systems, condensation on cooling coils, leaks, and clogged drain pans can lead to persistent dampness, creating the essential conditions for mold proliferation [1, 2].

- Abundant Organic Matter: Mold requires a food source to grow, and organic materials commonly found in building dust, dirt, and debris that accumulate in HVAC systems serve this purpose [1, 3]. These microscopic particles settle on moist surfaces, providing the necessary nutrients for mold to germinate and colonize.

- Concealed & Stagnant Conditions: The interior of large-scale HVAC units, air handlers, and extensive ductwork is typically dark and can have areas of stagnant air, which promote mold growth once spores establish themselves [2].

- Operational Cycling and Temperature Differentials: While large commercial systems operate to maintain precise temperatures, the constant cooling cycles create the necessary temperature differentials for condensation, further contributing to a mold-friendly environment.

Left unaddressed, mold in the HVAC system can lead to significantly reduced airflow, decreased system efficiency, unpleasant musty odors, and—most critically—the widespread dispersion of mold spores throughout occupied spaces. The Centers for Disease Control and Prevention (CDC) warns that mold exposure can cause a range of health issues, including respiratory problems, asthma exacerbation, allergic reactions, and irritation of the eyes, skin, nose, throat, and lungs [4]. For critical infrastructure, this can translate to operational disruptions, increased energy consumption, compliance challenges, and a compromised working environment.

Beyond Band-Aids: Proactive Prevention with Specialized Coatings

Many approaches attempt to address mold in HVAC systems, ranging from reactive cleaning protocols to frequent filter replacements. While these are essential components of a robust maintenance program, they often fall short of providing a true, long-term preventative solution, especially on the intricate surfaces where mold first takes root. The Occupational Safety and Health Administration (OSHA) explicitly states that the most effective way to prevent mold growth is to control moisture and to clean and dry any wet or damp building materials within 24-48 hours [3]. This is where advanced surface protection becomes invaluable.

Coat Zone understands that preventing mold in HVAC requires addressing the problem at its source: the susceptible surfaces themselves. Our specialized antifungal and antimicrobial coatings are engineered to create an inhospitable environment for mold and other microbial growth, significantly reducing the risk of contamination and deterioration within your commercial HVAC infrastructure.

How Coat Zone’s CoilSafe Solutions Offer Superior Protection:

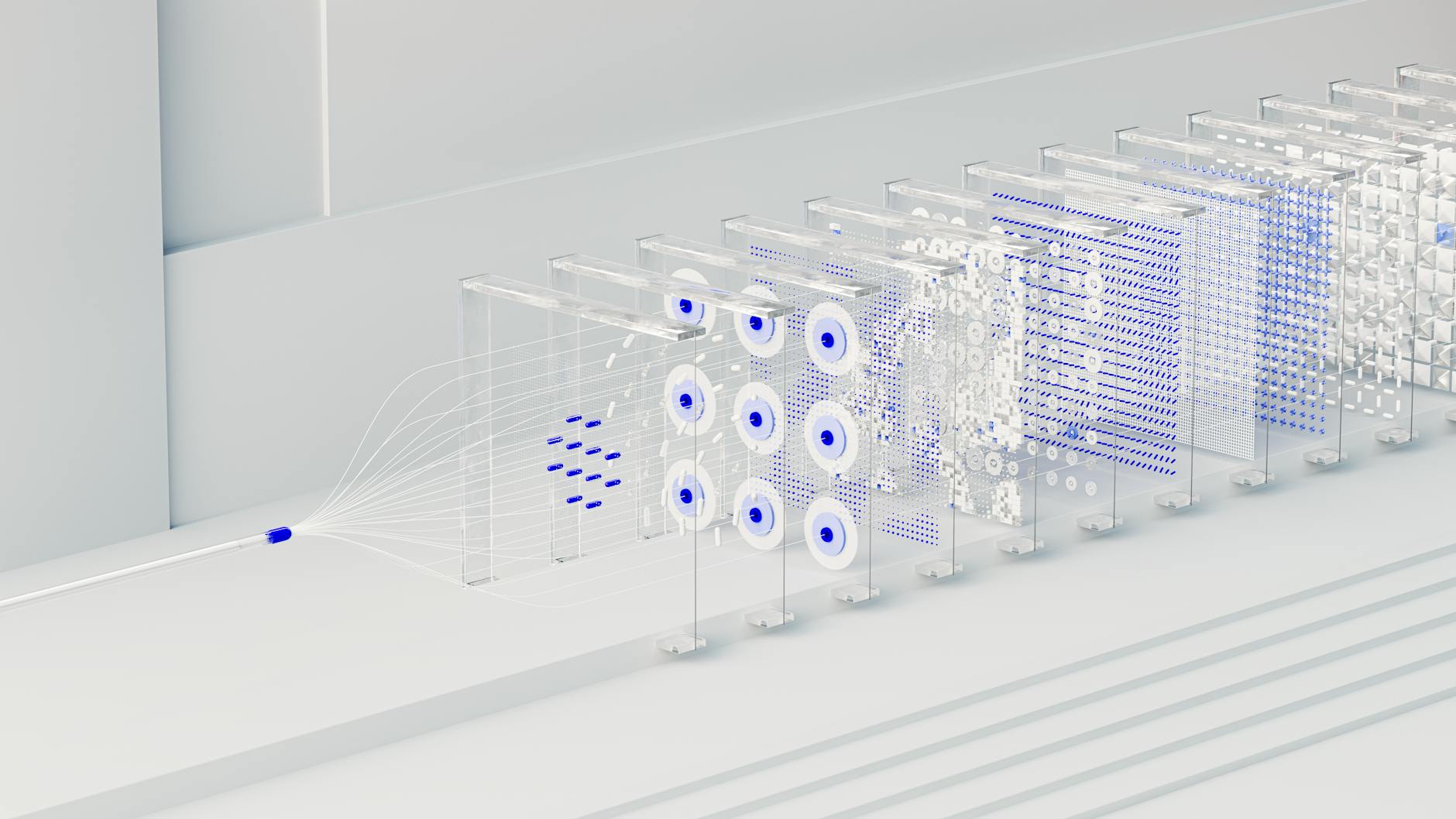

- CoilSafe®: This foundational coating is designed for the interior coils of your HVAC system. It provides a durable, smooth barrier that minimizes the adhesion of airborne organic matter, making coils easier to clean and significantly reducing the potential for microbial buildup [7]. By maintaining clean coils, CoilSafe ensures optimal airflow and heat transfer, thereby preserving system efficiency, which is crucial for large-scale operations.

- CoilSafe Plus®: Taking protection a step further, CoilSafe Plus® incorporates advanced antimicrobial properties directly into the coating. This active defense inhibits the growth of bacteria, mold, and other microorganisms directly on the coil surfaces [7]. These advanced properties create a microscopic environment on the coil where microorganisms cannot readily thrive or reproduce, effectively preventing biofilm formation and subsequent mold colonization, thereby offering an enduring barrier against mold in HVAC [7].

By applying these specialized coatings, you are not simply reacting to mold; you are proactively preventing its establishment and growth. This means:

- Improved Indoor Air Quality: Crucial for employee health and compliance in commercial settings.

- Enhanced System Efficiency: Optimized heat exchange and reduced energy consumption, directly impacting operational costs.

- Extended Equipment Lifespan: Protecting sensitive coil surfaces from biological degradation, prolonging asset life.

- Reduced Maintenance Costs: Less frequent and less intensive coil cleaning is required, resulting in minimized disruption.

For leaders in the infrastructure sector, investing in preventative measures like Coat Zone’s CoilSafe and CoilSafe Plus is not merely a maintenance expense—it’s a strategic decision that safeguards high-value assets, protects personnel health, and ensures the uninterrupted operation of critical facilities.

Partnering for Healthier, More Resilient Infrastructure

At Coat Zone, we are dedicated to providing the highest quality antifungal and antimicrobial coatings for your commercial and industrial HVAC systems. While we own these innovative coating technologies, we partner with a network of approved dealers who are experts in their professional application. This ensures that every installation meets our rigorous standards for effectiveness and durability, providing you with a reliable and long-lasting solution against mold in HVAC.

Don’t wait for mold to compromise your infrastructure. Take a proactive stance with Coat Zone’s proven solutions.

Take the Next Step: Schedule a Consultation

Are you ready to fortify your HVAC systems against the unseen threat of mold and ensure the highest standards of air quality and operational efficiency within your facilities? Contact Coat Zone today to schedule a consultation. Our experts and approved dealers are ready to discuss your specific needs and demonstrate how CoilSafe and CoilSafe Plus can provide the lasting protection your infrastructure deserves.

Sources:

- U.S. Environmental Protection Agency (EPA). “Mold Remediation in Schools and Commercial Buildings.” EPA 402-K-01-001, March 2001. Available at: https://www.epa.gov/mold/mold-remediation-schools-and-commercial-buildings-guide-chapter-1

- U.S. Environmental Protection Agency (EPA). “Should You Have the Air Ducts in Your Home Cleaned?” EPA Publication No. 402-K-97-002, October 1997. While focused on homes, the fundamental principles of condensation and moisture accumulation leading to mold in HVAC systems are universally applicable to commercial systems. Available at: https://www.epa.gov/indoor-air-quality-iaq/should-you-have-air-ducts-your-home-cleaned

- Occupational Safety and Health Administration (OSHA). “A Brief Guide to Mold in the Workplace.” OSHA Safety and Health Information Bulletin (SHIB 10-10-03), October 2003. Available at: https://www.osha.gov/publications/shib101003

- Centers for Disease Control and Prevention (CDC). “About Mold.” CDC, September 2020. Available at: https://www.cdc.gov/mold-health/about/index.html

- National Institute for Occupational Safety and Health (NIOSH). “Mold Testing and Remediation.” CDC/NIOSH. Available at: https://www.cdc.gov/niosh/mold/testing-remediation/index.html

- U.S. Environmental Protection Agency (EPA). “Mold.” EPA Website. Available at: https://www.epa.gov/mold